GUIL TMD-570 - Line Array Lifting Tower. Compact (Volume: 3.68 m3)

Couldn't load pickup availability

If you have any questions about this product, we can assist you by filling out the contact form

Ask an expert

The TMD-570 Line Array Lifting Tower is a compact and exclusive design from GUIL, specially created to lift Line Array equipment of up to 800 kg to a maximum height of 8 meters by means of a motor. GUIL's engineering department has designed a totally innovative tower certified for outdoor use under the European EN 13814 standard.

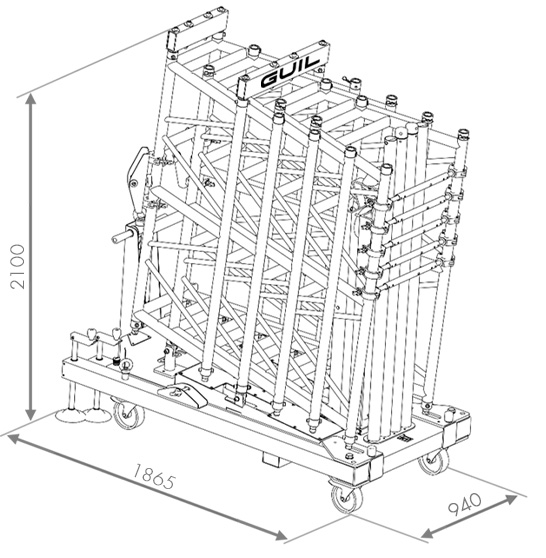

Its careful design offers quick and easy assembly. The TMD-570 tower is extremely manoeuvrable, all the tower components are housed without loose parts in a single base (with a volume of only 3.68 m 3 ), making it very easy to transport and store.

Supplied with the “ TMD-570 APC ” interactive application for outdoor use, taking into account the maximum wind forces permitted by applicable regulations.

| SPECS | TMD-570 |

| Maximum tower height: | 8.25 m |

| Maximum working height: | 8 m |

| Maximum load: | 800 kg |

| Material: | Aluminum (alloy 6082-T6 ) and Steel |

| Storage and transport measures: | Height: 2.10 m – Base: 94 x 187 cm – COMPACT design |

| Volume: | All in one piece: 3.68 m 3 |

| Use: | EXTERIORS and Interiors |

| Certified for outdoor use: | According to EN 13814 regulations |

| Verified for wind force: 8 Beaufort | |

| According to the Regulations: | 2006/42/EC EN 17206 (Replaces DIN 56950-1 ) DGUV 17 & 18, DGUV Standard 115-002 (Former BGV-C1 ) |

| Net Weight: | 360 kg |

| Color: | Black |

| Interactive tool: | “TMD-570 APC” (Included) |

AN INNOVATIVE SOLUTION:

When GUIL launched its first compact Line Array tower in 2003 (model TMD-545), it was a FIRST in the industry, its great popularity was based on its innovative design; reducing storage space and assembly times. The TMD-570 Line Array tower follows the innovative path opened by the TMD-545 tower, addressing the market needs for a compact tower, but with greater height and load capacity.

QUICK AND EASY ASSEMBLY :

Aware of the problems faced by technicians when installing sound systems of this type for outdoor events, GUIL has designed the PA tower Ref. TMD-570, which allows a single professional to raise the structure using an electric motor in a quick and easy way.

Its design allows the mast of the structure to be raised to a vertical position without the need for four or five people. With the TMD-570 tower, a technician needs only two minutes of assistance from a colleague to begin raising the mast before completing the lifting process with the engine.

COMPACT FOR STORAGE AND TRANSPORT:

With its ingenious one-piece design (no loose parts) and small storage dimensions (3.68 m3), coupled with its ease of transport and handling, the TMD-570 sound-lifting tower has a right to be considered one of the most practical structures on the market. A single technician can move the TMD-570 on its wheels from the truck to the assembly site with total ease, using the handlebars to steer it.

The TMD-570 model is the perfect solution for those events where a high-rise, high-load capacity Line Array tower is required and where storage and transport space are also an important factor.

The TMD-570 comes equipped with a chain bag Ref. BLC-01 to store the electric motor chain.

DESIGNED FOR OUTDOOR EVENTS: The TMD-570 tower has been specifically designed for outdoor use (although it can naturally also be used indoors), and is supplied with an interactive application, the “TMD-570 APC”, which helps the user to calculate the maximum permissible wind speed, according to the applicable EU regulations (EN 13814), taking into account the weight and height of the line array to be used in each case.

MAXIMUM SECURITY AND RELIABILITY: For GUIL, the most important thing is to manufacture products that guarantee maximum safety. For this reason, we only work with the most up-to-date technological solutions and the highest quality materials to fulfil the projects of our engineering department, and the TMD-570 tower is a clear example of this rule. The certified strength and stability of this tower, designed and built to lift 800 kg of line array equipment to a height of 8 metres, is achieved thanks to its intelligent design and reinforced construction.

MINIMUM TIME AND EFFORT:

The TMD-570 rigging tower has been designed to be as quick and easy to assemble as possible. The front legs of the tower are assembled on the base and pivot to lock into place. The lateral stabilizers are inserted into their housings and secured using reinforced magnetic pins (Ref. RC-100/L).

The trusses are assembled on the ground and then, thanks to the motor and the hinge system installed at the base, the structure is raised to its working position without any effort (all the work is done by the motor). This ensures quick and easy lifting and subsequent lowering of the structure.

The tower is levelled using the double-speed, double-pitch spindles fitted to the legs and side stabilisers, together with the spirit level fitted to the base. This system ensures quick and easy assembly and disassembly of the tower, which can be carried out by just two people.

The trapezoidal section trusses were created by GUIL's technical department with the aim of achieving a high-resistance mast specifically for outdoor use that, at the same time, was quick to assemble and took up the least possible space for storage and transport.

In addition to raising the sound system and placing the aluminium structure in its vertical working position, the motor chain also acts as a reinforcing brace, providing the tower with great strength and resistance. NOTE: It is recommended to use a motor with a load capacity of 1000 kg.

STRUCTURE:

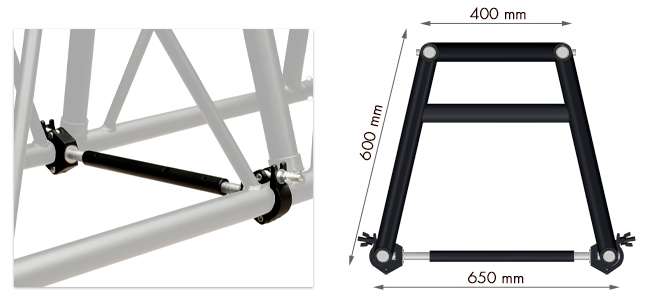

TRUSS SECTIONS: The mast consists of five 1500mm long trapezoidal trusses (400mm x 650mm x 600mm). These sections have been specially designed by GUIL engineers to provide maximum strength, whilst allowing them to be stacked together to reduce the space they take up during storage or transport. This means that when folded, the tower only takes up 3.68m3, making storage and transport more convenient and practical.

SPREADER ARMS: The truss sections each include a spreader arm to reinforce the structure and prevent deformation (5 spreader arms).

TENSIONERS : The tower is equipped with two tensioners or braces, which allow the tower to support heavy loads and maintain the stability of the structure. Each tensioner is attached, at its upper end, to the structure by means of a clamped connection and, at its lower end, to the front legs.

HEAD:

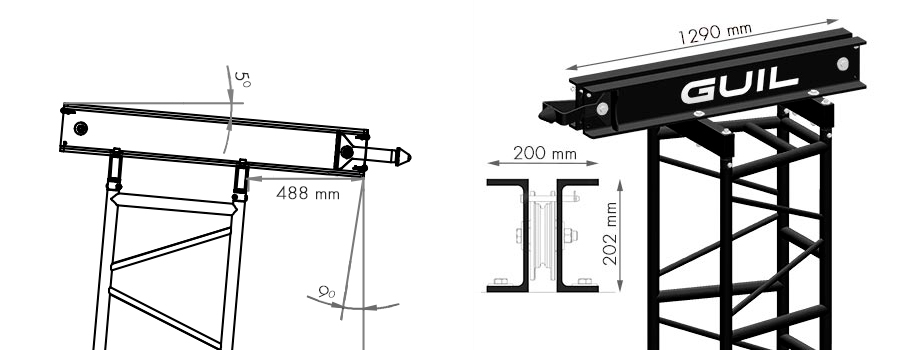

HEAD: The head consists of two high-strength 1290 mm aluminium beams which, in combination with the 5º inclination of the truss structure, ensures the correct degree of inclination of the line array system. It can be removed from the tower to be stored in the base, or placed on the ground to assemble the tower and install the motor chain. The head incorporates a large silentblock to protect it during assembly and disassembly of the tower.

BASE:

UNIQUE DESIGN : The base of the TMD-570 is the result of a revolutionary design and pioneering execution, with the dual purpose of being the base of the line array tower when in use and housing all the tower components in a single block for transport and storage, avoiding the loss of components. The base (with dimensions of only 940×1865 mm ) is provided with custom-made nylon protectors to prevent damage from scratches or bumps and keep your TMD-570 tower in perfect condition, and also has a bubble level to assist in the process of leveling the tower during assembly.

MOTOR ANCHORING: For the motor, GUIL has created a special support that fits under the base for transport and storage, but is removed to form an anchoring point for the chain, creating an arm that provides maximum strength and stability during the lifting process and subsequent use of the tower.

LEGS AND STABILIZERS: They are equipped with two removable legs and two lateral stabilizers that are housed in the base and are deployed during use of the tower. The four units are equipped with leveling spindles with double-thread thread for maximum effort work, with ergonomically designed knobs made of injected nylon that are highly resistant to impacts and non-slip discs designed for a perfect grip on all types of surfaces. The legs and lateral stabilizers provide maximum stability and resistance to the TMD-570 Line Array tower.

TRANSPORT: For easy transport, the base is equipped with four large (150 mm) swivel castors with brakes, making the TMD-570 very manoeuvrable, and a handlebar for steering. A single technician can move the base with all TMD-570 components wherever needed. One person moving a complete line array tower to lift 800 kg to 8 meters height: who can resist that?

SECURITY:

TMD-570: SAFETY IN LIFTING 800 KG LINE ARRAY EQUIPMENT

The TMD-570 rigging tower meets the safety requirements according to the following Rules and Regulations:

▪ Directive 2006/42/EC: relating to machinery and establishing the health and safety requirements that apply in the design and construction of machinery.

▪ EN 13814: Machinery and structures for fairs and amusement parks.

▪ EN 17206 (Replaces DIN 56950-1 ): Entertainment technology – Machinery for stages and other production areas – Safety requirements and inspections.

▪ DGUV Regulations 17 and 18: Accident prevention regulations. Facilities for events and production for stage performances.

▪ DGUV Standard 115-002: Production and staging facilities for the entertainment industry.

- Type Hardware and Scenarios

- Vendor GUIL

- SKU TMD-570

Buy GUIL TMD-570 - Line Array Lifting Tower. Compact (Volume: 3.68 m3)