GUIL ULK 500 PLUS - Front-loading lifting towers (for line array and truss)

Couldn't load pickup availability

If you have any questions about this product, we can assist you by filling out the contact form

Ask an expert

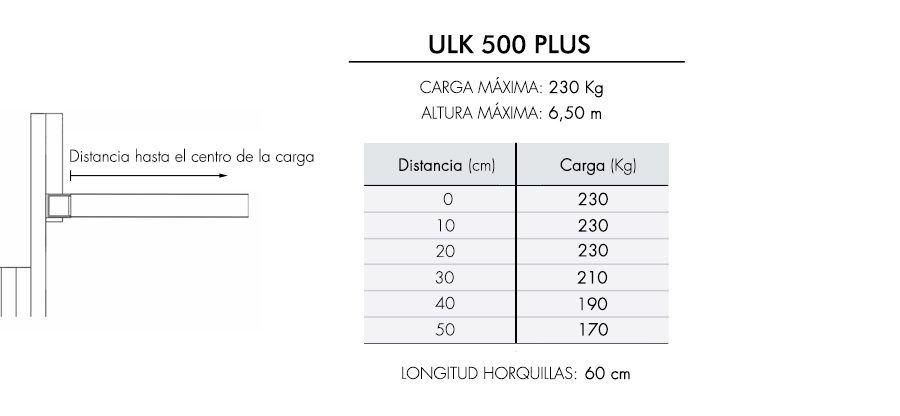

Lifting tower designed to lift loads of up to 230 kg to a maximum height of 6.50 meters.

Multi-purpose lifting tower, made of aluminium and steel, developed to lift and hold heavy loads at great heights.

Its compact design, easy handling (without the need to use any type of tool), unlimited number of applications and great resistance make the ULK 500 PLUS tower the ideal complement for any type of event.

| SPECS | ULK 500 PLUS |

| Maximum Height | 6.50 m |

| Maximum load | 230 kg |

| Security: | ASB System (Automatic Locking System) |

| IPB System (Internal Pendulum Brake) + MSU System | |

| Winch | Double crank |

| Folded Height | 1.98 m |

| Horizontal Transport | Included (2 wheels of Ø 100 mm) |

| Base Wheels | Fastening by plate with 4 screws |

| Leveling spindles legs | Trapezoidal thread TR24x5. Greater durability and speed |

| Material | Aluminum (Alloy 6082-T6 ) and Steel. Color: BLACK |

| According to the Regulations: | DGUV 17 & 18, DGUV Rule 115-002 (Former BGV-C1 ) |

| DIN EN 17206 (Replaces DIN 56950-1 ), 2006/42/EC | |

| Net Weight | 121 kg |

| Number of Sections | 4 (Profile width: 135 mm) |

SECURITY:

The ULK 500 PLUS tower is manufactured using the most advanced welding equipment, carefully selecting the materials used and controlling the quality of all its components during manufacture. This guarantees maximum safety and strength, always meeting the requirements of strength, stability, lightness and manoeuvrability required for lifting loads. Thanks to the special system for loading it onto vehicles, the easy placement of the load to be lifted and its simple and quick assembly, this tower is considered one of the most functional on the market.

The ULK 500 PLUS is equipped with three safety systems that guarantee maximum reliability during the lifting and lowering process of loads.

1.- Self-braking double-crank winch safety system: Once the desired height is reached, when the winch levers are stopped, its brake mechanism begins to act, preventing recoil and stopping the load at the desired height.

2.- ASB System (Automatic Locking Safety System): Composed of handles that allow the technician to lock/unlock each of the elevator sections.

3.- IPB System (Internal Pendulum Brake): This is an extra safety system consisting of an internal pendulum system, which is automatically activated in each section when it experiences a small fall speed and is unlocked by activating a trigger that each section has.

The ULK 500 PLUS towers are equipped with the MSU system (Section Unlocking System): Release trigger to unlock the internal pendulum brake without having to completely disassemble the tower.

VERY IMPORTANT: ULK TOWERS ARE NOT MADE FOR LIFTING PEOPLE.

Important: For outdoor installation, the structure must be secured using cables, slings, chains, etc. to prevent any unexpected movement due to strong winds.

The ULK 500 PLUS tower complies with the requirements of the Quality System according to the following Standards and Regulations: DGUV Regulation 17&18 – DGUV Rule 115-002 – DIN 56950-1 – 2006/42/EC

LOAD DIAGRAM:

BASE:

Compact 570 x 460 mm base made of steel with a double-treated epoxy textured paint finish for outdoor use.

The base is provided with:

– 4 heavy duty wheels: 2 swivel and 2 fixed (Ø100 mm), allowing the ULK 500 PLUS tower to be transported to your workplace with minimal effort (its dimensions allow access through standard-sized doors and corridors).

– 4 reinforcements made of steel with dual function:

1. For greater resistance in working position.

2. To protect the telescopic sections when loading the tower in a horizontal position.

Its four removable steel legs are equipped with double-thread leveling spindles for maximum effort work, with ergonomically designed knobs made of injected nylon that are highly resistant to impacts and non-slip discs designed for a perfect grip on all types of surfaces.

PROFILES:

Its four profiles made of high-resistance aluminium are extendable by means of sets of pulleys with bearings (coated with nylatron bushings) and Ø 5 mm galvanised steel cable with an inner steel core (Composition: 7×19+0) specially designed for lifting loads (DIN 3060).

FORKS:

The ULK 500 PLUS tower is equipped with reinforced 600 x 60 x 60 mm steel forks, where the load to be lifted is fixed at a height of 19 cm from the ground, facilitating quick and easy placement of the load (with magnetic pins for quick assembly).

Forks have 2 fundamental characteristics:

– Adjustable design ; to accommodate different sizes of loads.

– Detachable design ; for convenient transport and storage of the tower

APPLICATIONS:

TRANSPORT:

For horizontal transport and quick and easy loading into vehicles, the ULK 500 PLUS tower is equipped with two highly resistant Teflon wheels with bearings on their axle (Ø 100 mm).

- Type Hardware and Scenarios

- Vendor GUIL

- SKU ULK 500 PLUS

Buy GUIL ULK 500 PLUS - Front-loading lifting towers (for line array and truss)