GUIL TMD-545/N - Line Array Lifting Tower. Compact (Volume: 1.49 m3)

Couldn't load pickup availability

If you have any questions about this product, we can assist you by filling out the contact form

Ask an expert

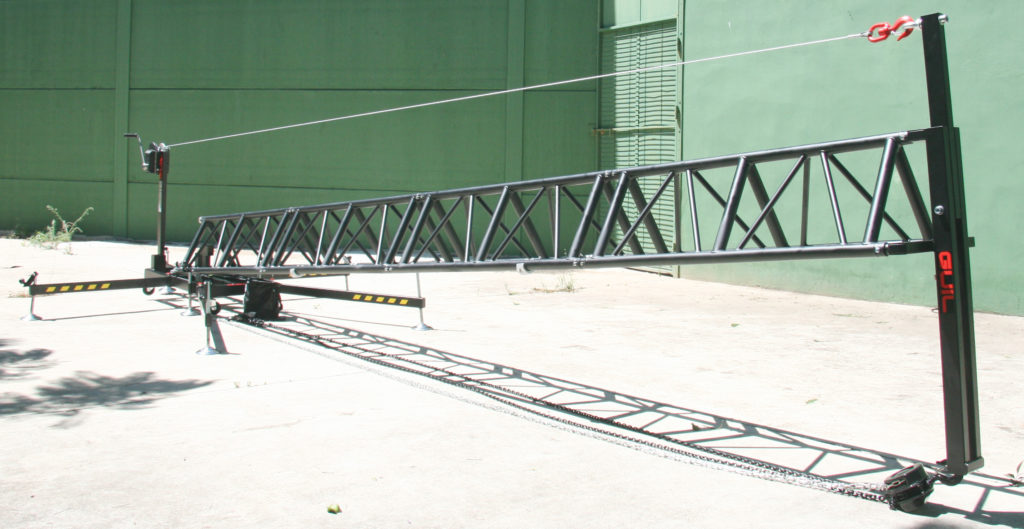

The TMD-545/N Line Array Lifting Tower is specifically designed to lift Line Array systems weighing up to 500kg to a maximum height of 6.25m by using a 2000kg Manual Hoist. GUIL's engineering department has designed a completely innovative tower, certified for outdoor use, that can be assembled and operated by a single person, with just two minutes of assistance from a colleague during assembly.

The TMD-545/N is equipped with a double-crank winch , which makes the work of assembling the tower easier and faster.

The TMD-545/N comes fully equipped with all the components and elements necessary for use: complete operating structure, with hoist for lifting and a double-crank winch for mounting, etc. You have a very complete tower, ready for use right out of the factory packaging. Carefully designed for easy assembly and handling, and the entire tower occupies only 1.49 m 3 in a single block for easy storage. The TMD-545/N tower is extremely maneuverable, easy to store, transport and position, and offers safety, strength and reliability in use. One of the most convenient and functional towers on the market, the perfect solution for your tours!

The TMD-545/N Line Array Systems Lift Tower comes with an interactive “ TMD-545/N APC ” application to calculate the maximum allowable wind speed for outdoor use.

| SPECS | TMD-545/N |

| Maximum tower height: | 6.43 m |

| Maximum working height: | 6.25 m |

| Maximum Load: | 500 kg |

| PA Lift System: | 2000kg Manual Hoist (Included) |

| Tower Lifting System: | Double crank winch (included) |

| Tower Structure – Truss: | Stackable 500 x 500 mm (4 units of 1500 mm) |

| Material: | Aluminum (alloy 6082-T6) and Steel (BLACK finish) |

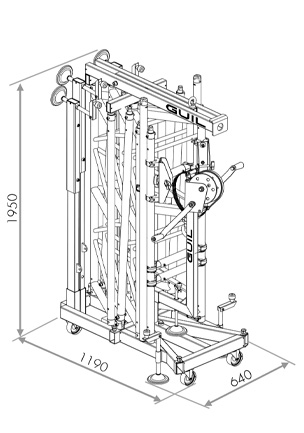

| Folded Height: | 195 cm (Unique design – compact) |

| Volume: | 1.49 m 3 (64 x 119 x 195 cm). All in one piece |

| Use: | EXTERIORS and Interiors |

| Certified for outdoor use: | According to EN 13814 regulations |

| Verified for wind force: 8 Beaufort | |

| According to the Regulations: | 2006/42/EC EN 17206 (Replaces DIN 56950-1 ) DGUV 17 & 18, DGUV Standard 115-002 (Former BGV-C1 ) |

| Net Weight: | 190 kg |

| Interactive tool: | “TMD-545/N APC” (Included) |

A REVOLUTION IN DESIGN:

QUICK AND EASY ASSEMBLY: Aware of the problems faced by technicians when installing sound systems of this type for outdoor events, GUIL has designed the TMD-545/N PA tower, which only requires one professional for its assembly. The double-crank winch allows the technician to raise the truss structure without the help of other colleagues. The help of another professional will only be needed for a couple of minutes to start raising the tower mast, and the same for its dismantling.

COMPACT FOR STORAGE AND TRANSPORT: With its ingenious single-block design (no loose parts) and reduced storage dimensions, only one block of 1.49 m 3 , coupled with its ease of transport and handling, the TMD-570 sound lifting tower has the right to be considered one of the most practical structures on the market. A single technician can move the TMD-570 on its wheels from the truck to the assembly site with total ease, using the handlebar to steer it. That's perfect for you! The TMD-545/N is ideal for touring and seasonal shows, as well as any other intermittent use where a high-height, high-load tower is needed and where storage space is also an important factor.

DESIGNED FOR OUTDOOR EVENTS: The TMD-545/N has been specifically designed for outdoor use (although it can naturally also be used indoors), and is supplied with an interactive application, the “TMD-545/N APC”, which helps the user to calculate the maximum permissible wind speed, according to the applicable EU regulations (EN 13814), taking into account the weight and height of the line array to be used in each occasion.

MAXIMUM SECURITY AND RELIABILITY: For GUIL, the most important thing is to manufacture products that guarantee maximum safety. For this reason, we only work with the most up-to-date technological solutions and top-quality materials to meet the projects of our engineering department, and the TMD-545/N tower is a clear example of this rule. The certified strength and stability of this tower, conceived and built to lift 500 kg of line array equipment to a height of 6.25 meters, is achieved thanks to its intelligent design and reinforced construction, to guarantee the protection of the sound equipment, the tower itself, and of course, the safety of the people near the tower at the event.

MINIMUM TIME AND EFFORT IN ASSEMBLY:

The TMD-545/N rigging tower has been designed to be as quick and easy to assemble as possible. The front legs and side stabilizers of the tower are housed in their sockets and secured with pins (Ref. RC-100). The truss sections of the TMD-545/N are designed to be assembled horizontally, before being attached to the hinges at the base of the tower and raised into working position. The seven spindles in the legs, side stabilizers and base, together with the spirit level, are then used to level the tower before use. This system allows for quick and easy assembly and disassembly of the tower, with the help of just two professionals.

The Line Array System will be lifted using the manual hoist (Ref. POLI/4), which has a certified capacity of 2,000 kg (CE). This hoist is provided with a 6 m chain, making it possible to lift the tower effortlessly. A reinforced bag (BLC-01) for the BLC-01 chain is also included.

The trapezoidal section trusses were created by GUIL's technical department with the aim of achieving a high-resistance mast specifically for outdoor use that, at the same time, was quick to assemble and took up the least possible space for storage and transport.

MODULAR STRUCTURE:

TRUSS SECTIONS : The mast consists of four 1500mm long trapezoidal trusses (500mm x 500mm), allowing the sections to be stacked vertically at the base for storage and transport and two adjustable bracing arms are supplied. The tower structure sections have been specially designed by GUIL engineers to provide maximum strength, whilst stacking together for storage and transport to take up just 1.49m3 . when stored on their wheeled base.

REINFORCING BARS: The tower itself is equipped with two braces, which are secured to the trusses by two clamps and to the front legs with specially designed brackets, forming a strong and very stable structure.

UPPER SECTION:

The head consists of two high-strength 1190mm aluminum beams and a 400mm extension that projects from the back.

Its front part has two functions:

1.- The front of the upper truss section measures 760 mm long, and this, combined with the 3º inclination of the truss structure, ensures the correct degree of inclination of the line array system.

2.- Acts as a robust arm to fit the 2T chain hoist that lifts the Line Array System.

Its rear part has two functions :

1.- Allows professionals to fasten the winch brake safety hook. The hinge system at the base of the tower allows the mast structure to be raised almost effortlessly, with only the intervention of a technician.

2.- Once the tower is fully assembled, the winch can be slightly adjusted to obtain a stability effect with counterweights.

BASE:

UNIQUE DESIGN : The base of the TMD-545/N is the result of a revolutionary design and pioneering execution, with the dual purpose of being the base of the line array tower when in use and housing all the tower components in a single block for transport and storage. The truss sections and other components, including the winch and hoist, are located in the base of just 640×1190 mm , thus forming a compact block that prevents the loss of pieces during storage and transport.

The base also comes with a spirit level to level the tower before use, with the help of the spindles.

WINCH MOUNTING : The TMD-545/N's dual-crank winch is attached to a special frame that snaps into the base for easy transport and storage. For assembly, the winch is installed on the tower where it forms an anchor point for the cable. This creates a support that gives the tower great strength and stability, and further support for when the Line Array System is raised.

The winch handles, specially designed for lifting heavy loads, are removable, to prevent any unauthorized manipulation during use of the tower.

LEGS AND STABILIZERS: The TMD-545/N's legs and side stabilizers, housed vertically in the base, are extendable to ensure that the tower has a large stable safety area. The legs and stabilizers are equipped with leveling spindles, made entirely of steel with rubber discs at their base, to ensure that the base is level before use. Additionally, there are three more spindles at the base of the tower, making a total of seven spindles, all fitted with chrome-plated steel discs for added sturdiness and reliability. The spindles have double-pitch threads for maximum effort work, which allows the tower to be raised very quickly. When the legs and stabilizers are extended, the spindles are deployed to level the tower, ensuring 360° support essential when people are around the tower when it is assembled and in use.

TRANSPORT: For easy transport, the base is equipped with four large wheels (100 mm diameter) with brakes and a handlebar for steering, making the TMD-545/N an extremely manoeuvrable tower. A single technician can move the base with all the TMD-545/N components wherever needed. One person moving a complete line array tower to lift 500 kg to 6.25 meters high: who can resist that?

MAXIMUM SECURITY:

TMD-545/N – SAFETY LIFTING OF LINE ARRAY EQUIPMENT, 6.25 METERS 500 KG

The TMD-545/N rigging tower meets the safety requirements according to the following Rules and Regulations:

▪ Directive 2006/42/EC: relating to machinery and establishing the health and safety requirements that apply in the design and construction of machinery.

▪ EN 13814: Machinery and structures for fairs and amusement parks.

▪ EN 17206 (Replaces DIN 56950-1 ) : Entertainment Technology – Stage Equipment and Other Production Areas – Safety Requirements and Inspections.

▪ DGUV Regulations 17 and 18: Accident prevention regulations. Facilities for events and production for stage performances.

▪ DGUV Standard 115-002: Production and staging facilities for the entertainment industry.

When GUIL introduced its TMD-545 Line Array Tower, it was a pioneer in the events sector, with great success due to its ingenious design, which allowed the entire tower to be placed on a single base, thus reducing storage space and assembly time. It is worth noting that the tower is remarkably light for its height and load capacity. This tower model has been improved over the years. It is currently manufactured in black, with epoxy paint finish, which makes it more discreet at concerts and other events.

Due to the success of the TMD-545/N, GUIL has continued to investigate the needs of professionals in the events sector, allowing it to design new towers and other products, thus offering a range of original and compact towers that allow lifting a greater load to a greater height, such as the TMD-570 tower.

- Type Hardware and Scenarios

- Vendor GUIL

- SKU TMD-545/N

Buy GUIL TMD-545/N - Line Array Lifting Tower. Compact (Volume: 1.49 m3)