GUIL TM441 - Aluminum and steel scissor-type platform. 5 positions. Birch plywood (21 mm).

Couldn't load pickup availability

If you have any questions about this product, we can assist you by filling out the contact form

Ask an expert

Stage platform. Maximum load of 750 kg/m 2 . Includes connectors

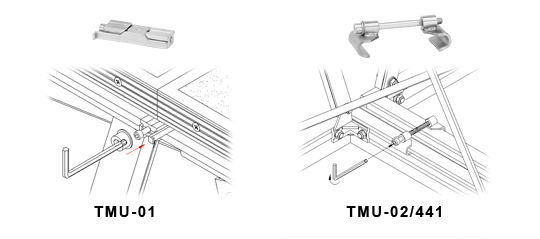

High-resistance modular platform of 2 x 1 m with a compact design, made of extruded aluminum (frame), reinforced steel (base structure) and non-slip phenolic panel with water-repellent and fire-retardant treatments, 21 mm birch wood, with non-slip finish and edges sealed. 2 metal connectors included: 1 TMU-01 and 1 TMU-02/441.

| SPECIFICATIONS | TM441 |

| Maximum load | 750 kg/m 2 (7.5 KN/m 2 ) (2×1 m: 1500 kg) |

| Board | > Birch Wood > Thickness: 21mm > Phenolic plywood (WBP) |

| Certification according to regulations | DIN 15921 Entertainment technology |

| DGUV Regulation 17 & 18, DGUV Rule 115-002 |

|

| Environment | FSC certificate |

| PEFC certificate | |

| Fire resistance | Classification: B-s1 (according to regulations: DIN EN 13501-1 ) |

| Non-slip behavior | R-13 (according to regulations: DIN 51130 ) |

| Material | Aluminum , alloy EN AW 6063 80-T6 |

| Base: Reinforced steel structure (DIN 2393) | |

| Connectors included | 1 x TMU-01 and 1 x TMU-02/441 (stainless) |

| Applications | Interior and exterior |

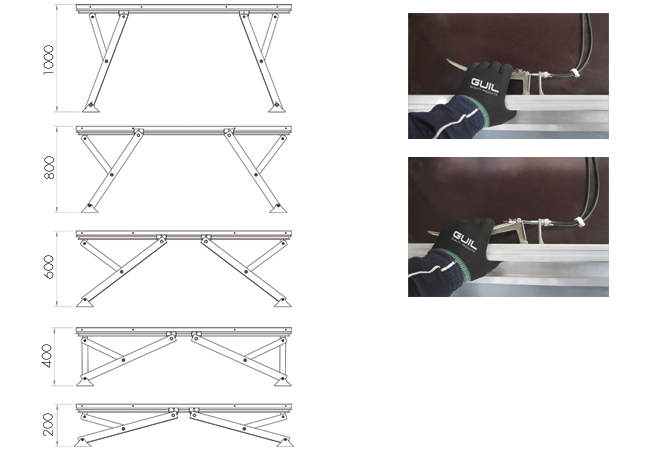

| Heights | 20cm/40cm/60cm/80cm/100cm |

| Extent | 2×1m |

| Net weight | 67kg |

| Storage height | 20cm |

The TM441 Platform has a wide range of applications, and can be used independently (for batteries, tracking guns) or joined together to form ramps, stages, podiums, walkways, stands, etc., becoming a very practical element due to its great stability, resistance and quick assembly.

As it is a completely compact platform, there is no possibility of component loss, making it an exceptional platform for any temporary assembly.

The TM441 Pallets combine versatility with stability, great resistance and easy assembly. They offer the best solution for any type of event, from small setups to large stages, and can be used in multiple configurations for both permanent and temporary installations (concerts, theaters, auditoriums, conservatories, forums, etc.).

GUARANTEED SECURITY:

Our TM441 Pallets are certified for 750kg/ m2 under the following standards:

- DIN 15921:2015-09 : Technical safety and testing requirements for aluminum platforms and frames in the entertainment industry.

- Directive 2001/95/EC: Product safety requirements of the European Parliament of December 3, 2001

- DGUV Regulation 17: Installations and set-ups of Stages for the Entertainment Industry

- DGUV Rule 115-002: Installations and set-ups of Stages for the Entertainment Industry

These regulations require a safety factor of 1.65.

BOARD:

TM441 pallets are equipped with a birch wood panel, 21 mm thick .

The panel, provided with a non-slip finish through special hot printing, is composed of layers glued with weather- and water-resistant phenolic resin (WBP).

The board is subjected to water-repellent and fire-retardant treatments, as well as treatments against commonly used chemicals. These features ensure the highest strength and durability for both outdoor and indoor applications.

To make this panel safer and more durable, all its edges have been sealed with acrylic paint, preventing the penetration of moisture.

You can request the board certificates from our Engineering department.

The board used, made ONLY from birch wood, is specially designed for those applications where non-slip properties are required along with great wear resistance. The multi-layer construction ensures that the board is very compact and resistant.

The panel used complies with the following Regulations and Standards:

– EN 13986:2004+A1:2015

– EN 314-2/class 3

– DIN 53799

– DIN 5113

Our pallets are designed for indoor and outdoor use. Important: The panel of our pallets is water resistant, IT IS NOT WATERPROOF. In case of rain, humidity or other inclement weather, they must be disassembled and stored. They can withstand short periods exposed to rain and humidity. They are not designed to be used as a permanent outdoor installation where they may be exposed to extreme conditions all year round.

Boards yes, but from sustainable forests.

That is why at GUIL the boards we use to manufacture our pallets carry the FSC seal (Forest Stewardship Council, or Forest Management Council) which guarantees that the products come from well-managed forests, in this way, consumers can choose from responsible manner.

Thanks to its weather-resistant birch phenolic board, its aluminum structure and its legs with an Epoxy finish, the TM441 pallets are perfect for outdoor use.

FRAME:

The TM441 pallet is built with a strong, high-load capacity aluminum frame with a special 85 mm profile.

Its multifunctional continuous guide design guarantees quick and easy joining of pallets to each other and allows simple and quick adaptation of a wide variety of accessories (handrails, access stairs, skirts, coverings, seats, etc.).

The panel is fixed to the frame structure using three fastening systems: high fixation foam, stainless steel screws, and silicone, thus avoiding possible noise and vibrations and at the same time providing the platform with great resistance to the elements. time.

TRIPLE FASTENING SYSTEM from board to profile by:

* High fixation foam

*Stainless steel screws

* Silicone

Our pallets do not need reinforcement bars, since their components guarantee maximum safety (reinforced profile, 21 mm BIRCH WOOD and fixing elements); exceeding the load required in the regulations during test tests.

HEIGHTS:

The TM441 platform is provided with an independent height adjustment system that allows five different positions:

► 20, 40, 60, 80 and 100 cm .

Each of the meter sides of the TM441 scissor platform is equipped with an internal lever; The height adjustment system is activated by pressing the lever that allows the steel pins to be locked and unlocked, thus allowing the height of each side of the platform to be independently adjusted. This regulation system allows you to form ramps and inclined surfaces without the need for any additional tool.

UNION SYSTEMS:

The TM441 platform does not require any type of tool for assembly. Each TM441 Pallet is supplied with the two necessary joints for secure fixing:

TMU-01 Quick anchoring system for TM440, TM440XL, TM300 and TM441 pallets by joining their profiles (guide). This system, injected into metal with a zinc-plated finish, is designed to prevent the separation of pallets placed at the same height.

The anchoring and leveling union ref. TMU-01 is a very useful component as it ensures that there is no gap/joint or unevenness between the modules. Note: 1 unit is included for each Pallet.

TMU-02/441 Allows the union of the pallets internally, frame to frame; reinforcing the entire modular composition of the stage. (Made of stainless steel)

BASE STRUCTURE:

The leg structure is made of high-strength steel. Its anthracite-colored Epoxy paint finish allows it to be assembled outdoors, guaranteeing good maintenance of the platform and preventing rusting of any of its parts. The base is provided with non-slip steel tilting terminals for adaptation to any type of surface. Its special height adjustment system allows each side of the structure to be adjusted independently.

The manufacturing of this modular platform is carried out with the most advanced technology; carefully selecting the materials used and controlling the quality of all its components during manufacturing. This guarantees maximum security and firmness; complying at all times with the requirements of solidity, lightness and maneuverability necessary for setting up stages. The combination of all these characteristics makes this reinforced platform a very practical element for all those events that require great load resistance with quick and easy assembly.

DOWNLOADS:

- Type Hardware and Scenarios

- Vendor GUIL

- SKU TM441

Buy GUIL TM441 - Aluminum and steel scissor-type platform. 5 positions. Birch plywood (21 mm).